- Home Page

- Company Profile

-

Our Products

- Air Dryer

- Industrial Chillars

- Compressed Air Treatment Accessories

-

Industrial Cylinders And Parts

- Short Stroke SDVU-L Series Compact Cylinder

- Short Stroke SQ2 Compact Cylinder

- SPM Micro Cylinder

- Clamp cylinder

- Tandem Cylinder

- Multi-Position Cylinder

- Standard Tie Rod Profile Air Cylinder

- Standard Micky Mouse Profile Air Cylinder

- Adjustable Stroke Cylinder

- Twin Rod Cylinder

- Standard Round Body Profile Air cylinder

- Cylinder Mountings

- Short Stroke SDVU-S Compact Cylinder

- Piston Rods

- 2 Wire Magnetic Reed Switch

- 3 Wire Magnetic Reed Switch

- Magnetic Reed Switch Clamp

- Cylinder Mounting

- ISO Standard Pneumatic Cylinder

- Push Touch Fitting

- Pneumatic Tubing

- Compressed Air Preparation Unit

- Solenoid Valves

- 2 2 Process Control Valve

- Valve Accessories

- Brass Fitting

- Air Compressor Silencer

- Flow Control Valve

- Recoils Hose

- Contact Us

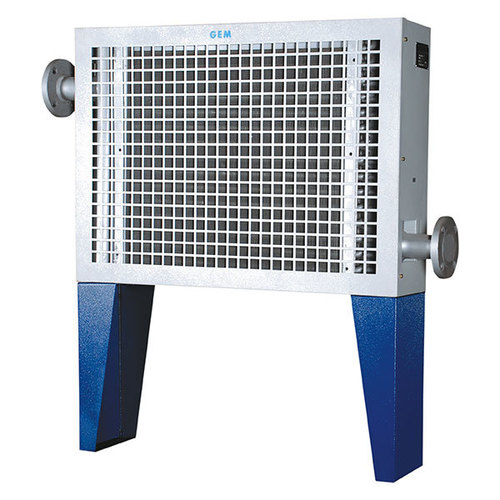

Air Cooled After Cooler

MOQ : 1 Piece

Air Cooled After Cooler Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- to pay

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Open Body

- Main Domestic Market

- All India

- Certifications

- Certificate will be provided if required

About Air Cooled After Cooler

Air Cooled After Cooler

Air cooled After Coolers are of fine-tube construction with the compressed air passing through the tube. Air Cooled After Cooler transfer the heat from the compressed air to the atmosphere. The compressed air is cooled using a cooler fan. Air Cooled After Coolers are preferred because it is easy to install and no additional pipe lines for water and easy to maintain.

Durable Powder-Coated Design

Our after coolers powder-coated surface significantly increases resistance against corrosion and wear, ensuring long-term durability even in challenging industrial environments. This protective layer enhances the coolers maintenance-free operation and supports stable performance in medium-pressure systems.

Energy-Efficient Cooling Performance

Designed for low working temperatures and powered electrically, the Air Cooled After Cooler securely manages thermal loads in compressed air setups. Its aluminum construction aids rapid heat dissipation, promoting energy savings and reducing operational costs over prolonged use.

FAQs of Air Cooled After Cooler:

Q: How does the Air Cooled After Cooler operate in medium pressure systems?

A: The Air Cooled After Cooler utilizes an electrically-powered fan to remove heat from compressed air as it flows through aluminum tubes, efficiently cooling the air to desired low temperatures suitable for medium pressure applications.Q: What is the benefit of a powder-coated surface on the after cooler?

A: The powder-coated surface offers enhanced protection against corrosion, abrasion, and chemical exposure, increasing the lifespan and reliability of the after cooler, especially in industrial environments with demanding conditions.Q: When is it recommended to use an air cooled after cooler in industrial settings?

A: It is best used when controlling the temperature of compressed air is necessary to prevent equipment damage and improve process efficiency, particularly in scenarios where cooling water may not be readily available.Q: Where are these after coolers typically installed and supplied across India?

A: These after coolers are commonly installed near compressors in manufacturing plants, workshops, and processing industries. We supply them across India, serving as a distributor, manufacturer, supplier, and trader for various industrial sectors.Q: What is the process for integrating an Air Cooled After Cooler into an existing system?

A: Integration involves connecting the after cooler immediately after the compressor discharge line, ensuring proper alignment and secure fittings. Electrical connections for the fan must be configured according to site specifications, followed by routine system checks.Q: How does aluminum construction contribute to the coolers efficiency?

A: Aluminum offers excellent thermal conductivity, facilitating rapid heat transfer and dissipation. This material choice ensures efficient cooling performance, reduces weight, and supports the units overall longevity.Q: What are the usage advantages of the Air Cooled After Cooler for Indian industries?

A: Using this after cooler increases air quality by lowering moisture and temperature, protects downstream equipment, enhances process reliability, and provides cost-effective cooling without the need for chilled water systems.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Compressed Air Treatment Accessories Category

Air Receiver Tank

Price 25000-500000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Storage Tank

Color : Blue/Silver

Surface : Powder Coated

Structure : Other

Air Moisture Separator

Price 1800-15000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Moisture Separation Type

Color : Blue/Silver/White/Red

Surface : Powder Coated

Structure : Diaphragm

Auto Drain Valve

Price 1500-8900 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Pilot Operated Type

Color : Black/Gold/Silver

Surface : Painted

Structure : Ball

Compressed Air Filters

Price 1300-10000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Industrial Type

Color : All Colors

Surface : Polishing

Structure : Diaphragm

Send Inquiry

Send Inquiry